HIGH PRESSURE DIE CASTING PARAMETER CALCULATION ALUMINUM ALLOY

PARAMETER CALCULATION IN HPDC

THERE ARE THREE PHASES IN HPDC MACHINES

1 FIRST PHASE :- Slow speed

2 SECOND PHASE :- High Speed

3 THIRD PHASE :- Intensification Pressure or Casting Pressure.

pouring hole

1 FIRST PHASE :- Slow speed

It is the distance start from plunger starting position to the distance traveled by plunger by which metal reached at cavity gate area.

2 SECOND PHASE :- High SpeedIt is the Distance traveled by plunger in which casting filled in cavity.In this distance plunger traveled with its high speed of the stroke.

How to calculate that travelling distance of plunger that filled the alloy in cavity.

The minimum velocity that will generate atomized flow is roughly

defined by the formula:

[Gv]1.7 x [gate thickness] x [weight density (r)] > 750

This says the minimum Gv (gate velocity) will be defined by the gate thickness

and Gv to the 1.7 power. Thus a thinner gate will require a higher

velocity to maintain atomized flow.

The maximum Gv will be determined by the onset of erosion and soldering

in the die, and the velocity where this occurs for a particular situation

should be a judgment of the gate designer. This judgment includes

consideration of the type of cast material, the type of die material, shape of

the cavity, and the fill time.

2 SECOND PHASE :- High SpeedIt is the Distance traveled by plunger in which casting filled in cavity.In this distance plunger traveled with its high speed of the stroke.

How to calculate that travelling distance of plunger that filled the alloy in cavity.

The minimum velocity that will generate atomized flow is roughly

defined by the formula:

[Gv]1.7 x [gate thickness] x [weight density (r)] > 750

This says the minimum Gv (gate velocity) will be defined by the gate thickness

and Gv to the 1.7 power. Thus a thinner gate will require a higher

velocity to maintain atomized flow.

The maximum Gv will be determined by the onset of erosion and soldering

in the die, and the velocity where this occurs for a particular situation

should be a judgment of the gate designer. This judgment includes

consideration of the type of cast material, the type of die material, shape of

the cavity, and the fill time.

Very nice..more useful

ReplyDeleteNice blog! Sharing a good information to me for any information Zinc Die Casting to visit our website:-https://www.thediecasting.com/

ReplyDeletePlease explain injection pressure and casting pressure calculations

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi Dear

ReplyDeleteI have read your post and it's very interesting post. I have achieved valuable thoughts from your post. Thanks for sharing such great post...

China die casting manufacturer offers the best casting parts, such as high pressure die casting, aluminium die casting, zinc die casting and sand casting etc.

If you would like more information, Visit Site

Aluminium die castings

ReplyDeleteAluminum Casting China company is offering good quality aluminum die casting, aluminum casting parts, aluminium die casting,if you need die casting china?

Aluminum die casting company

ReplyDeleteAre you looking the best die casting company? We are A die casting manufacturer in china that offers aluminum die casting, magnesium die casting, die casting products.

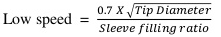

Sir I am Mithlesh Mishra want to in low speed calculation i used.

ReplyDelete0.7*tip dia/sleeve filling ratio

what is 0.7

Sir confirm about above .

ReplyDeleteThanks for sharing the best information and suggestions, If you are looking for the best precision aluminum die casting supplier, then aluminum die casting. Highly energetic blog, I’d love to find out some additional information.

ReplyDeleteJob recruitment. Us available or not

ReplyDeleteWonderful article, Which you have shared about the pintuu. Your article is very important and I was really interested to read it. If anyone looking for die casting companies then visit pintuu, It’s the best choice.

ReplyDeleteThank you for sharing that. Keep up the good work. OEM die-casting Parts

ReplyDeleteNice Information, your blog is sharing unique information....

ReplyDeleteThanks for sharing!!!

Aluminum die Casting

This comment has been removed by the author.

ReplyDelete